Do you feel discomfort when you think about replacing your refrigeration equipment? Do you count the time that will be spent on delivery, assembly and stocking? After all, this is the time when your store is closed to customers and you don't want that time to go to waste. Of course, devices must eventually be changed. It is best for those that will be not only newer, but also well-designed to enter a new, better time with their arrival. For example, SiX counters, which are easy and quick to install.

What does "easy assembly" actually mean? For us, it is primarily speed and work with ready devices. We bring them in, assemply together, clean and they are ready to work. It sounds interesting? Check how the assembly of a line of refrigerated display counters looks like in 3 simple steps.

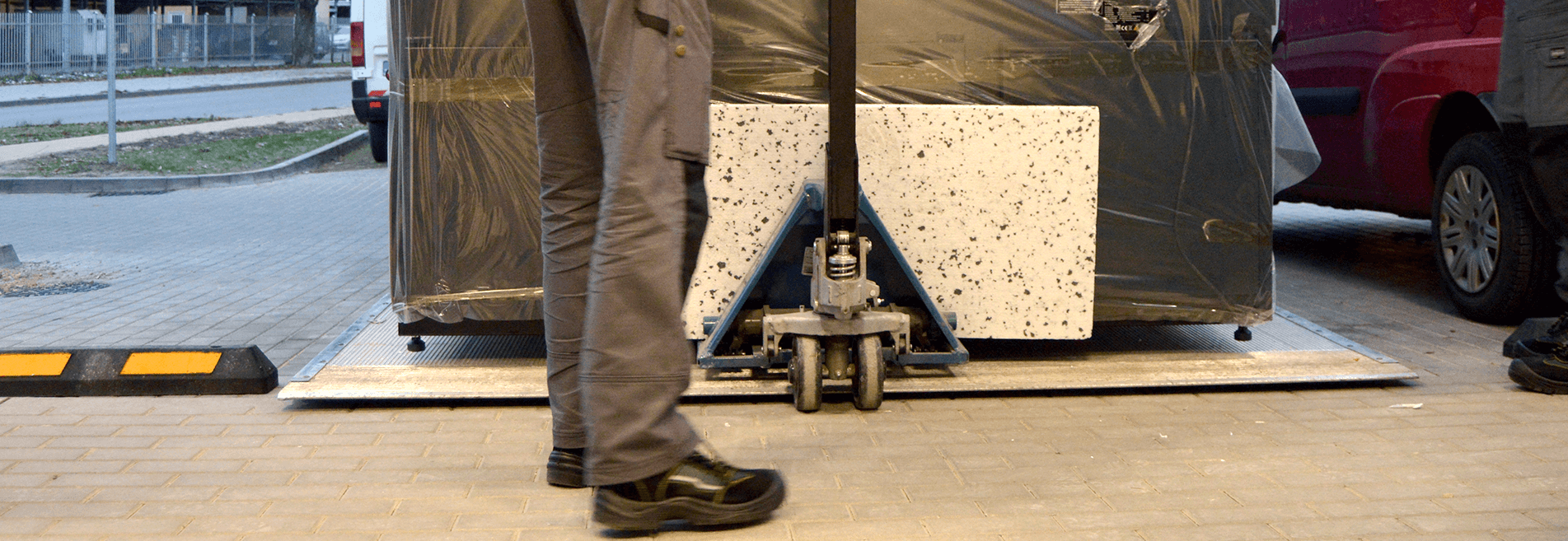

Step 1: deliver it safely to your destinatio

We transport the finished devices in a car with a lift, thanks to it and a low-profile pallet truck, we unload them quickly and safely. Why do we transport ready counters? Because it is more efficient and easier, we do not want to waste your time unnecessarily, after all, the device must also be loaded with goods.

All the elements that you can remove from the counter arrive secured with a protective film and immobilized (the counter is additionally protected by polystyrene). They need to be taken out before assembly so nothing gets damaged.

Step 2: set the string and connect the devices tightly and solidly

At the beginning, we set the base and add modules to it. Thanks to the adjustable feet, we can easily level the string. Connect the modules with appropriate screws in 4 places and seal them with silicone. Thanks to this, we prevent the penetration of moisture into the interior and between the modules.

Correct sealing is also a guarantee of proper operation of the cooling system. We put the silicone on carefully and without haste.

Step 3: clean and test the device

We hand over the counters ready for use, which is why we remove the protective foil from all moving parts. Surprisingly, this is the most time-consuming operation of the entire assembly.

Finally, we clean the windows and countertops so that everything shines ready for loading. We also test the device at this time. In the case of counters SiX we check not only the cooling system, but also an independent drying system for windows, which prevents the deposition of moisture on the display windows, even on the hottest days.

Cooling counters from the SiX line are ready to work

You're probably wondering how much time did this assembly consume? For these three counters, it took around 3.5 hours to set up and connect the string. Of course, it all depends on the type of devices, the length of the line and the space that we have at our disposal. Therefore, before arrival, we carefully inspect the place, advise and arrange details.

Do you want to see how it works? You can select and configure devices without any fees or obligations on our website. Do you prefer to talk? Call or write, we are here for you.