Device features

Finish available

Refrigerated cabinet ' open

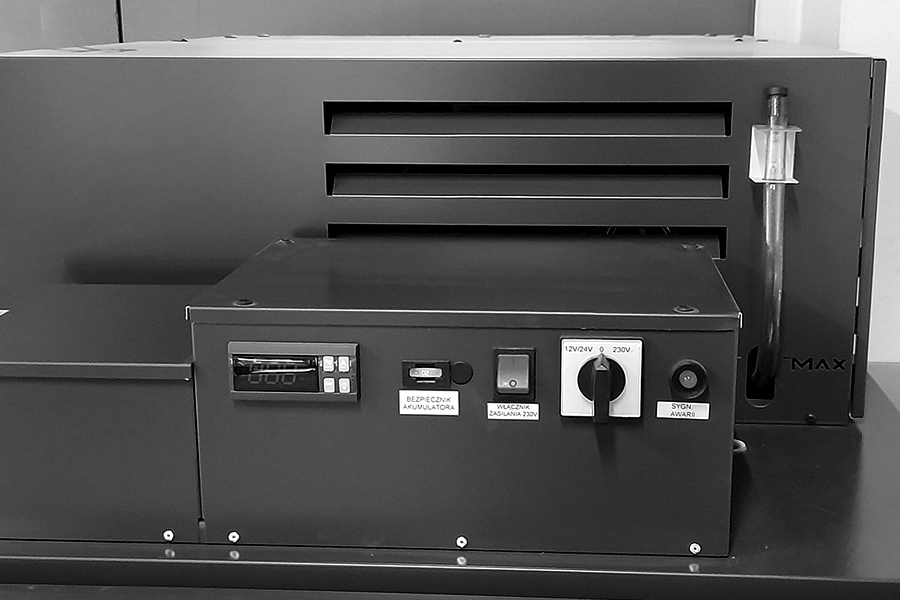

Refrigerated cabinet powered by various sources

We have designed the Cargo cabinet so that it can work in transport and at store. You can connect it in your car and transport products safely in low temperatures, or use it like any other refrigerated cabinet when plugged into a socket in the store.

Easy transport thanks to the pallet structure base

The cabinet was built with transport in mind, so its base has a shape similar to a standard pallet. Thanks to this, you can safely and conveniently carry it, without having to buy additional tools.

Condenser at your fingertips

No tools are required to access the condenser. It is enough to unfasten the buckle located next to the grille and slide the grille to the left. As a result, maintenance and cleaning are performed quickly and without problems.

Temperature under control

We have equipped the Cargo with an air guide to ensure the best possible temperature distribution on all four planes throughout the chamber.

Double protection against the accumulation of condensate

The device is equipped with an automatic condensate evaporation system that does not require maintenance. We've also added an extra container to allow excess water to drain into if too much of it ever builds up.

An interior open to your needs

The Cargo cabinet is insulated with ecological polyurethane foam. The interior is empty, so you have free space.

Safe transport is our priority

The device has protection against battery discharge, so you can always safely start the vehicle.

| Parameters | |||

| Cargo 500 | Cargo 1000 | ||

| climatic class | 3 | ||

| temperatures range | -1°C ÷ +4°C | -1°C ÷ +4°C | |

| +4°C ÷ +7°C | +4°C ÷ +7°C | ||

| refrigerant (HC) | R-600a | ||

| rated voltage | 230 V~ / 50 Hz; 24 VDC; 12 VDC | ||

| rated power | 140 W | ||

| defrosting | automatic | ||

| evaporation of condensate | automatic | ||

| model | Cargo 500 | Cargo 1000 |

|---|---|---|

| width [mm] | 780 | 780 |

| depth [mm] | 1190 | 1190 |

| height [mm] | 1340 | 2000 |

| interior width [mm] | 680 | 680 |

| interior depth[mm] | 990 | 990 |

| interior height [mm] | 750 | 1410 |

| usable capacity [l] | 500 | 950 |