Device features

Finish available

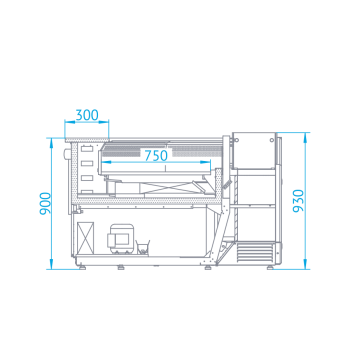

Back of the device

Wood-derivative board Yosemite S016

Wood-derivative board Oak Charlestone H3154

_50a35f41.jpeg)